Overview

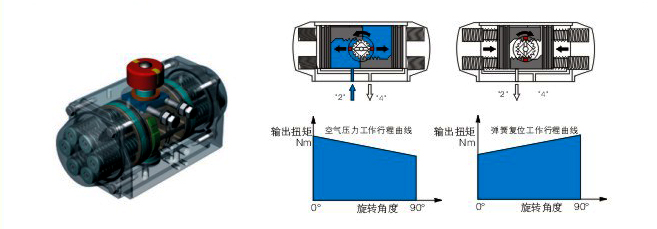

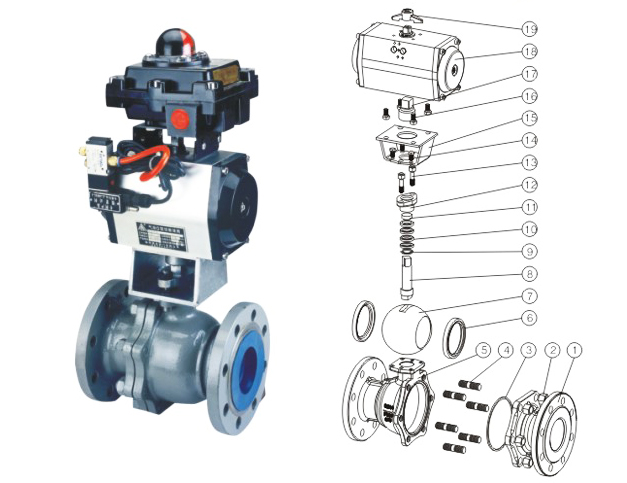

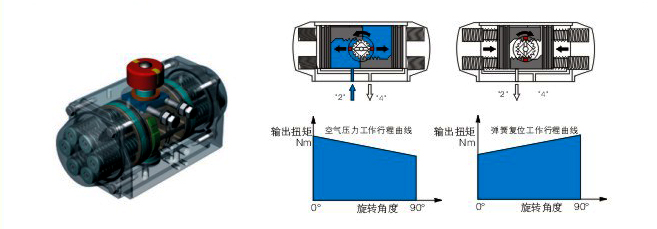

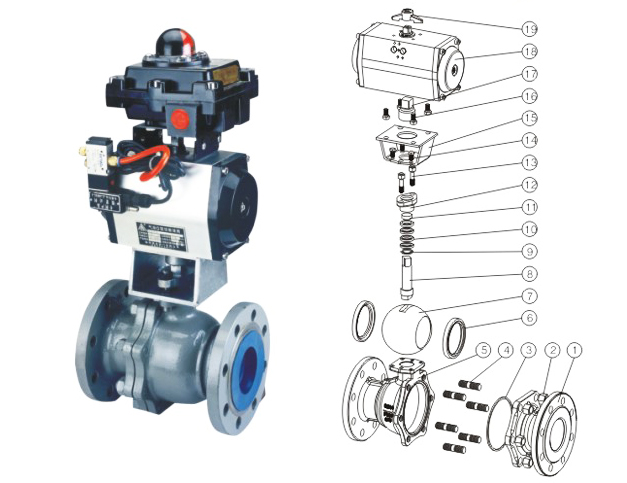

The Q641F pneumatic O-type ball valve consists of a ball valve and a pneumatic single-acting, double-acting actuator. The ball valve is a floating structure, an elastic sealing ring, a high temperature ball valve and an automatic compensation function. The actuator adopts a novel gear and rack-type double-piston pneumatic actuator. The whole machine has the advantages of novel structure, small size, light weight, reliable sealing, long service life and simple operation. It can be widely used in the automatic adjustment and remote control of petroleum, chemical, metallurgy, electric power, textile, medicine and other processes.

Structural features

The floating ball valve structure of Q641F pneumatic O-type ball valve is mainly composed of valve body, joint, ball, valve stem, sealing valve seat, packing and pressure plate. The sealing valve seat is processed by special sealing material and has good elasticity. High-temperature ball valve When the temperature rises, the automatic compensation part can adjust the deformation of the elastic sealing seat, thus making the sealing more reliable and longer. The actuator adopts a rack-and-pinion type double-piston actuator, which is mainly composed of a cylinder, a piston, a pinion, a cylinder head, a piston sealing ring, an adjusting bolt, an O-ring and the like. It has the characteristics of small volume, large torque, precise rotation angle and long service life. When combined with the ball valve, the overall shape of the machine is more beautiful and the service life is longer.

working principle

The actuator is connected to the ball valve with a connecting shaft. When the air source signal is input to the actuator chamber, a certain thrust is generated on the piston, and the valve shaft is rotated by the gear shaft to drive the ball to rotate, and the flow surface is changed to achieve the control purpose.

Double acting principle

Single-acting working principle

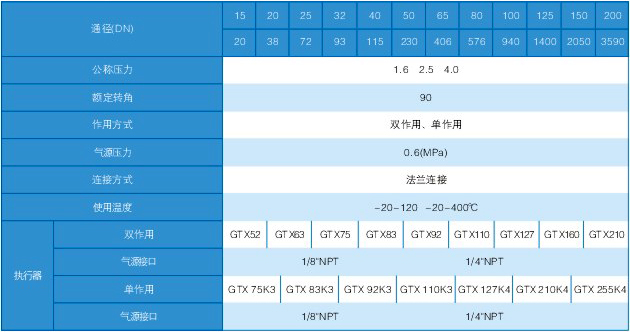

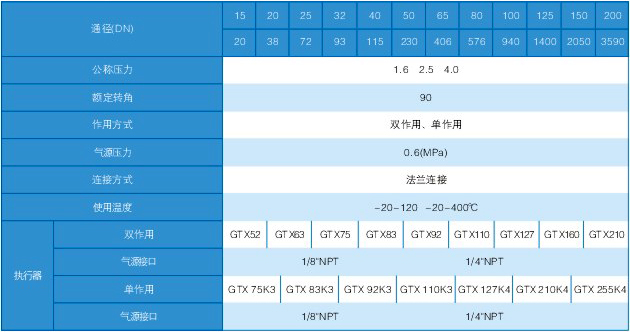

Main Specifications

Note: If special requirements, the actuator quality may not match the table

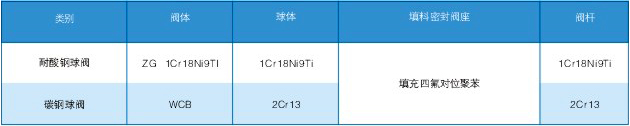

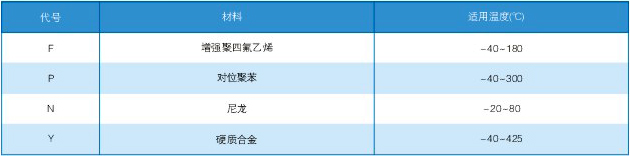

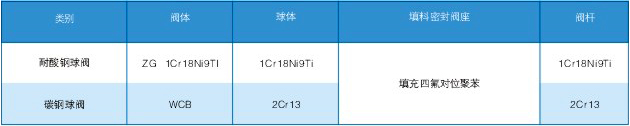

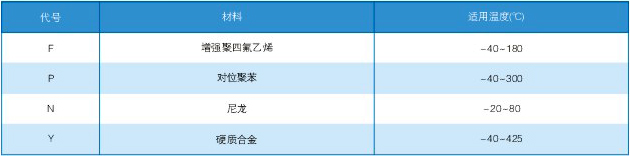

Main material

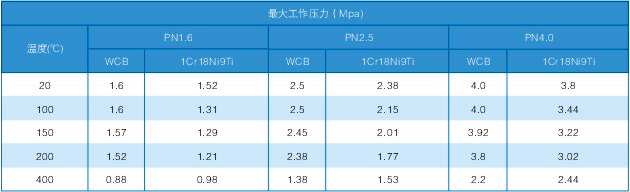

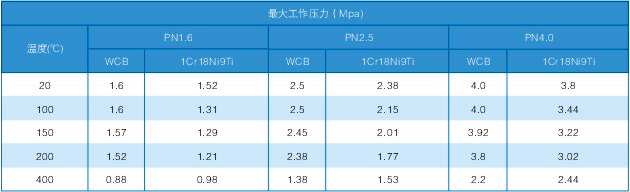

Use temperature and pressure ratings

Seat seal material temperature rating

Attachment options

The following accessories can be selected according to different controls and requirements:

Cut-off type accessories: single electric control solenoid valve, double electric control solenoid valve, limit switch return device.

Adjustable accessories: electrical positioners, pneumatic positioners, electrical converters.

Air source treatment accessories: air filter pressure reducing valve, air source treatment triple piece.

Manual mechanism: HVSD series

specifications

Note: The series ball valve structure length and connecting flange size can be designed and manufactured according to user requirements.

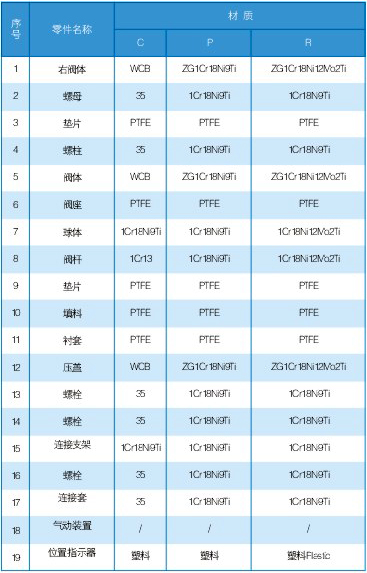

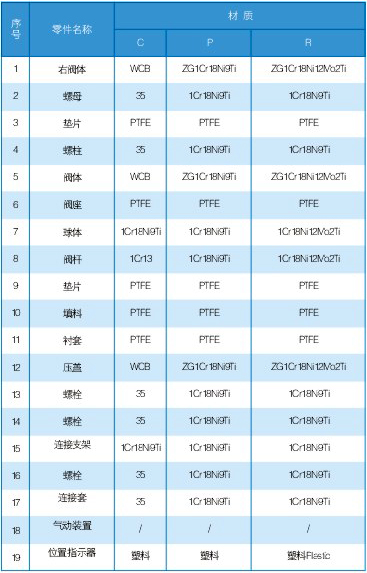

Main part material table

Note: The main components of the series ball valve and the material of the sealing ring can be designed and selected according to the actual working conditions or special requirements of the user.

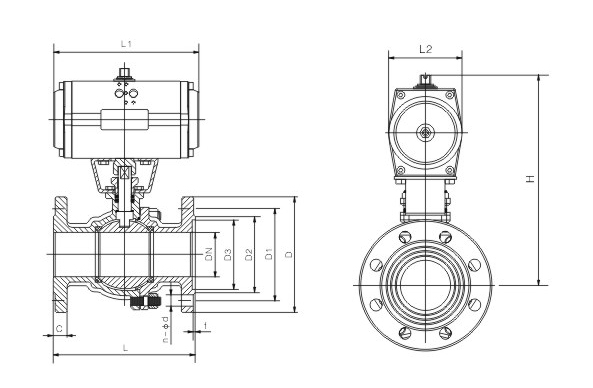

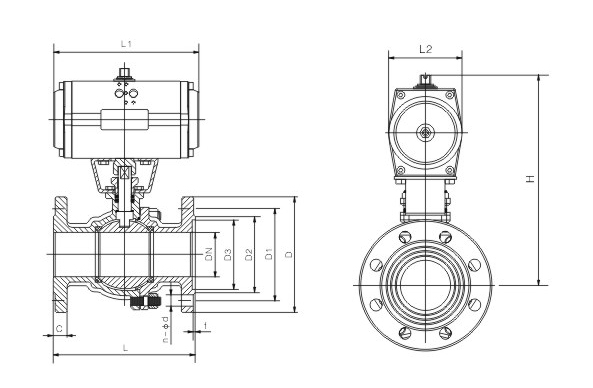

Main shape and connecting flange size (QPQ641(F, N, P)-16(1.6Mpa))

Main shape and connecting flange size (QPQ641(F, N, P)-25(2.5Mpa))

Main shape and connecting flange size (QPQ641(F, N, P)-40(4.0Mpa))

Note: The main components of the series ball valve and the material of the sealing ring can be designed and selected according to the actual working conditions or special requirements of the user. Note: The main components of the series ball valve and the material of the sealing ring can be designed and selected according to the actual working conditions or special requirements of the user. Note: The main components of the series ball valve and the material of the sealing ring can be designed and selected according to the actual working conditions or special requirements of the user.