Contact : 0591-83629908

0591-83362502

0591-83357911

Address: No. 7, Block 3, Datong Home International Electric Mall, No. 49 Fuxing Avenue, Jinan District, Fuzhou City

Copyright © Fujian Quanpai Valve Technology Co., Ltd. All Rights Reserved. 闽ICP备05012720号 Powered by 300.cn

Scan Code Attention

Online customer service hotline

4007002669

Products

QPGKPQ242X series high pressure composite exhaust valve

Page view:

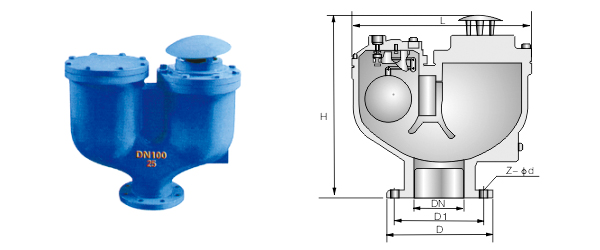

QPGKPQ242X series high pressure composite exhaust valve

Summary information

The valve is designed in the pump outlet or in the high-pressure water distribution pipeline to use a large amount of air in the conduit to enhance the efficiency of the water pipe and the pump,

Affiliate classification

Exhaust valve series

I want to make an inquiry

Description

use

The valve is designed in the pump outlet or in the high-pressure water distribution pipeline to use a large amount of air in the conduit to enhance the efficiency of the water pipe and the pump, and the valve can be quickly opened when a negative pressure occurs in the pipe. Inhalation of a large amount of air to damage the storage line due to negative pressure

Principle of action

When the water injection starts in the tube, the floating ball stays in the open position, and a large amount of exhaust is performed. When the air is exhausted, the water floating ball in the valve body is floated to the closed position, and a large amount of exhaust is stopped, when the tube is normally transported, such as A small amount of air collects in the valve to a considerable extent, the water level in the valve drops, and the float drops, and the air is discharged from the small hole. When the water pump or the high-pressure water distribution pipeline stops sending water, when the water in the pipe is empty or when a negative pressure is generated in the pipe, the float ball is lowered at this time, leaving the sealing surface, and a large amount of air is sucked to ensure the safety of the pipeline. (Note: The nominal pressure is 2.5MPa. The company is equipped with a buffer device)

Technical Parameters

1. Use medium: water

2. Medium temperature: normal temperature

3. Body strength test pressure: 25MPa,

4. Floating ball sealing test pressure: 0.07-1.76MPa

5. Body material: QT400-15 WCB

6. Float material: stainless steel

7. Flange connection standard: GB/T17241.6-98

8. Pressure test standard: Q/YECO1-2003

Composite exhaust valve shape and flange connection size table

Previous article

QPP41X type quick exhaust valve

QPGKPQ42X series high pressure composite exhaust valve

Next article